1. Down and Feather Filling Method for Quilt and Mattress

2. Filling Methods for Down & Feather Clothes

3. Filling Method for Pillow and Cushion

4. Specification Selection of Down and Feather Filling Machine When Offering an Order

Our machines can NOT weigh the feathe filled automatically.

1. Down and Feather Filling Method for Quilt and Mattress

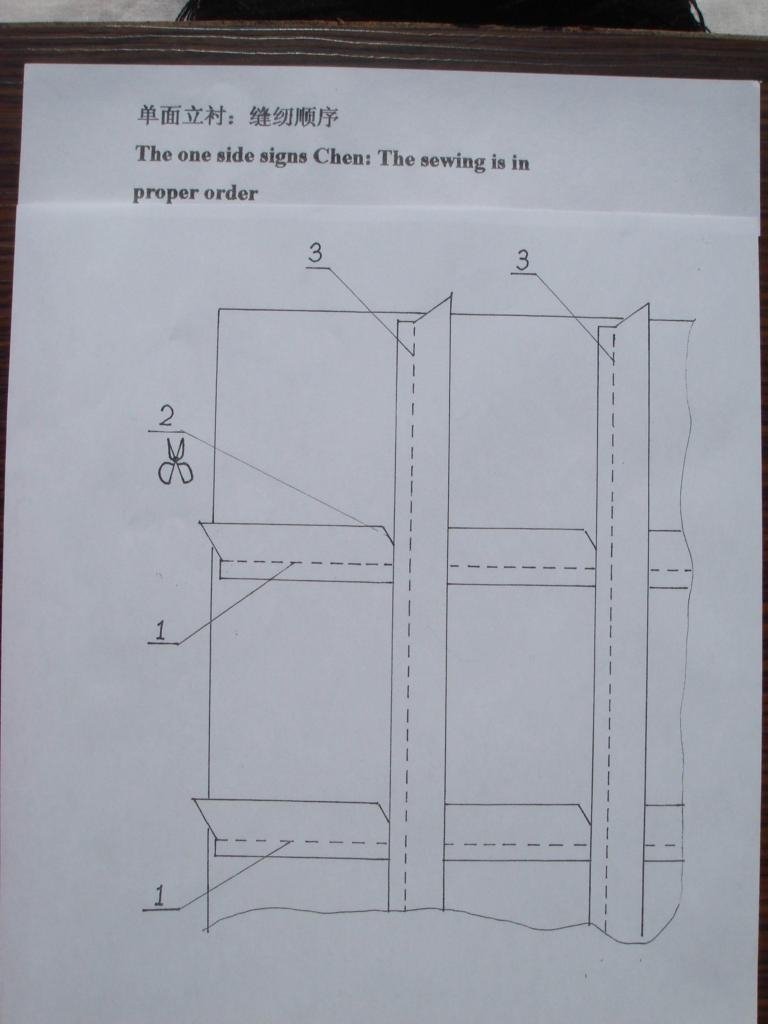

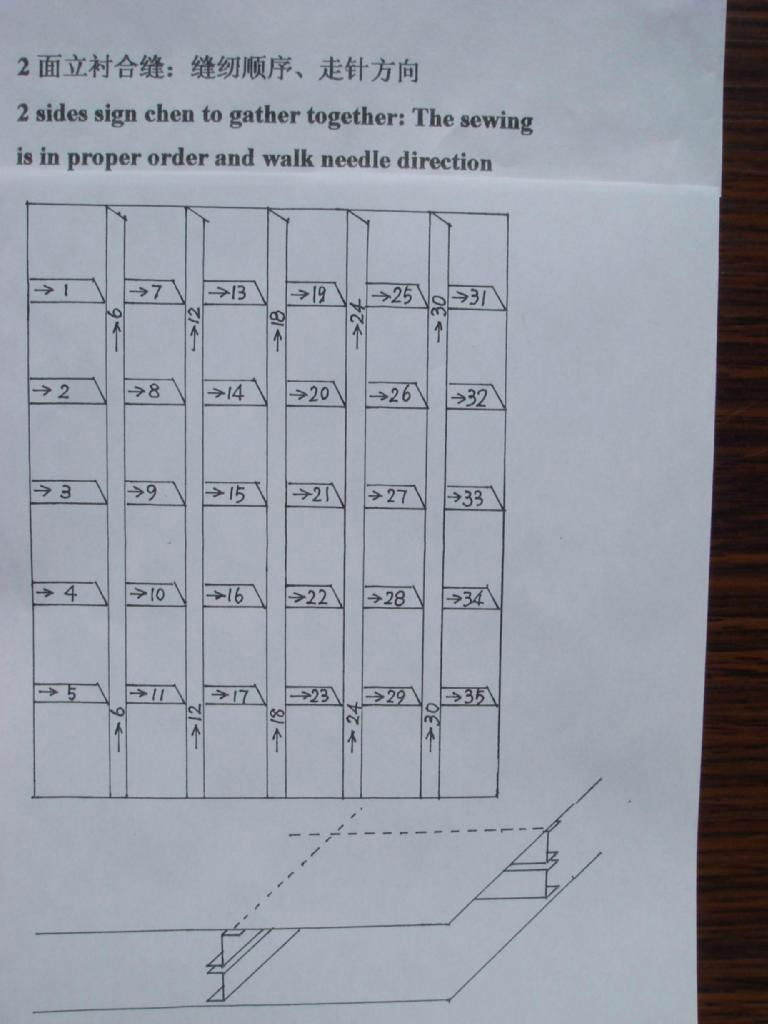

(1) Single check filling method

Applicable for: Export products with strict requirements

No.of Worker: 2

Equipment: 1 small down and feather holding

1 electronic desk scale with small weighing capacity

( 3 kilograms ± 1 gram ).

Method: Weigh manually down and feather for one check of the quilt or mattress. Fill all the weighed down and feather into the check..

It is suggested to use 2 electronic box scales (ACS-300X2) down and feather in turn in order to quicken up the filling speed. the working place can be kept clean all the time.

Advantage: The down and feather filled into each check are exact in weight; It is easy for the operator to master the down and feather filling technique.

Disadvantage: It is slow in filling speed; The total weight of a quilt may have some accumulative error.

(2) Single work piece filling method

Applicable for: On spot filling for sale in shop and sample manufacturing in workshop.

No. of Worker: 1

Equipment: 1 big down and feather holding box 620 x 520 x 750 (mm), 1 electronic desk scale with big weighing capacity ( 30 kilograms ± 2 grams ).

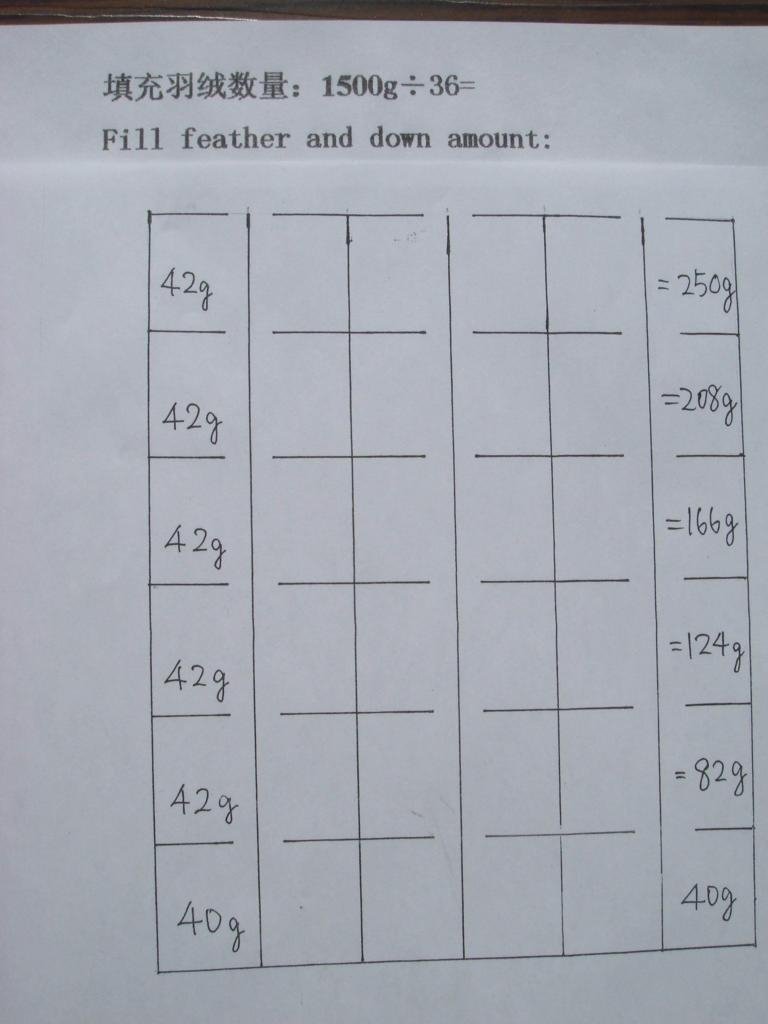

Method: Weigh manually in the box certain weight of down and feather enough for 1 quilt, for example, 1500 grams and fill them into 6 bars, that is 250 grams should be filled into each bar. Start the filling fan.

When the filling operation is just started, the operator should put the opening of the down and feather suction pipe close to the down and feather for quick suction; When the filled weight approaches 250 grams, the suction pipe should be raised a little for reducing the suction speed; when the filled weight reaches 250 grams, switch off the filling machine. Repeat the procedure for the next bar. When the operation goes on, the weight of down and feather in the box should be displayed as 1500, 1250, 1000, 750, 500, 250 and 0.

Advantage: There is no error in the total weight of each quilt.

Disadvantage: There may be errors for the weight filled in each bar if the operation is not done proper enough, and the over-filled down and feather in the bar is difficult to take out.

(3) Continuous filling method

Applicable for: Large scale production in factory

No. of Worker: 2

Equipment: 1 big down and feather holding box 750 x 650 x 700 (mm), 1 electronic desk scale with big weighing capacity ( 30 kilograms ± 2 grams ). 1 desk type down and feather stand with declined desk surface, length

Method: Put a whole bag of down and feather on the stand. Fill the holding box full without caring about the weight. Press the “ tare deduction “ key to make the weight displayed as “

Advantage: It is the quickest filling method. Within 8 hours working time 200 pieces of 8-bar type down and feather quilts can be filled; What is more, the total weight error for each quilt or mattress is very small.

Disadvantage: The two operators must be well coordinated; There may be errors for the weight filled in each bar if the operation is not done proper enough, and the over-filled down and feather in the bar is difficult to take out.

Two automatic weighing barrels are used to weigh down and feather in turn. The operator need only insert the filling pipe into the quilt or mattress, and the machine will automatically blow in the weighed down and feather from the barrel.

Advantage: A. Filling speed is 30 % quicker than manual operation.

B. The working site is in good order and looks luxurious.

Disadvantage: Its price is expensive

The machine occupies 20

Filling weight is sometimes more than fixed errors.

The feather automatically circles for many times, and the consumption is large.

Filling Methods for Down & Feather Clothes

Method 1: filling machine

Down and feather are weighed on electronic scales with the precision of 0.2--1 gram., Fill with your hand the down and feather inside to the suction inlet and put the outlet of the fan into the space between the surface cloth and inner cloth. Let the fan blow the down and feather into the space. The display screen of the electronic scale can show the weight of down and feather already filled in.

Advantages:

A. Down and feather can be filled with filling pipes as small as

B. Down and feather can be loosened during filling procedure, which makes it easier to become smooth when patted by hand in the following working procedure ..

C. Person little contact feather.

D. Down and feather filling machine can be used to produce down and feather quilts and other products. Down and feather quilts are easy to produce and high in benefit.

Disadvantage:

A. There is no big speed difference in down and feather weighing and filling between filling machine and manual filling.

B. The working place tends to get disordered and spreaded with loose down and feather.

Method 2: hand stuff

Due to the fact that down & feather clothes are small in down and feather quantity filled and short in filling passage, they are usually filled manually.

On an electronic scale with a standing display screen, put an open box of 400 X 500 X

Method 3: funnel stuff

On a desk type electronic scale, put a funnel made with thin iron sheet with a height of

Method 4 Automatic down and feather filling machine

Two automatic weighing barrels are used to weigh down and feather in turn. The operator need only insert the filling pipe into the quilt or mattress, and the machine will automatically blow in the weighed down and feather from the barrel.

Advantage: A. Filling speed is 30 % quicker than manual operation.

B. The working site is in good order and looks luxurious.

Disadvantage: Its price is expensive

The machine occupies 20

Filling weight is sometimes more than fixed errors.

The feather automatically circles for many times, and the consumption is large.

(1) fiber ball

3-dimensional curling of chemical fiber ---- Pearl size chemical fiber ball forming machine ---- Filling machine for pillow ---- Weight checking with electronic scale ---- Sealing of the opening with sewing machine

Advantage: Simple in production technique, minimum in seal length and the quickest in filling speed. Smooth in pillow appearance and full in four corners. For cushions with special structures, their appearance are also smooth.

Can be also Fixed weight filling machine for pillow.

The products are high in technical element, endurable and high in sales price.

Disadvantage: Only 3-dimensionally curled chemical fiber can be adopted, 2-dimensionally curled chemical fiber can not be used. Raw material is expensive.

(2) carding and Fixed weight filling machine for pillow

Chemical fiber ---- chemical fiber carding machine ---- Filling fan ---- Weight check with electronic scale ---- Sealing of the opening by sewing machine

Advantage: Less operators are needed because of the production line formed with carding machine and filling machine.

Good in apparent smoothness of the pillow.

Disadvantage: The pillow has a long seal. It is not applicable for small cushion and cushion with a special shape.

Slow in production speed in production line due to the small production speed of the carding machine.

Error of fixed weight is about 50 grams. Check of weight is still necessary.

Chemical fiber ---- Felt forming by chemical fiber carding machine ---- Manual felt- cutting into pillow size ---- Filling with fitting plates ---- Sealing of the opening with sewing machine

Advantage: Investment is reduced by making use of the existing chemical fiber carding machine.

The pillow thus filled is smooth in appearance with four full right angled corners.

Disadvantage: The seal is as long as the width of the pillow itself.

It is slow in production speed.

Purchasing of loosened chemical fiber, feather, fiber ball ---- Manual filling ---- Weight checking with electronic scale ---- Sealing of the opening with sewing machine

Advantage: No investment for equipment is needed.

Disadvantage: It is not smooth in the appearance of the pillow.

The pillow has a long seal. Production speed is slow.

(5) Filling machine for pillow

Purchasing of loosened chemical fiber, feather, fiber ball ---- Filling machine for pillow ---- Weight checking with electronic scale ---- sealing of the opening with sewing machine

Advantage: Full in the four pillow corners, small in seal, suitable

to make small products with special shapes and simple in equipment requirement.

Disadvantage: Some lumps of chemical fiber may be filled into the

pillow affecting the smoothness of the pillow appearance.

/>

Output of the pearl size chemical fiber ball forming machine: 50-

Output of chemical fiber loosening machine: 150-

Output of chemical fiber carding machine: 50-

Output of filling machine for pillow:

Parameters for reference:

4. Specification Selection of Down and Feather Filling Machine When Offering an Order

(1) Selection of fan with internal brake

D type Fan with brake is the first choice: Out going of down and feather for filling must stopped two seconds after the machine is stopped. This kind of fan is good enough to keep both the product and the site clean and to reduce the loss of down and feather. But it is high in price.

C type Fan without internal brake is selectable for self-employed persons and small workshops to reduce investment. It does not stop running during operation and is fast in filling speed. However, the site is difficult to keep clean and tidy because there is still little down being blown out 30 seconds after it is switched off.

E type fan with a frequency inverter, if selected, is easy

to adjust its wind force as required. Low wind force can be adopted when filling clothes or down and feather to decrease the damage of down and feather; strong wind force can be selected when filling pillows or big feather pieces to minimize the blockage of the filling pipe. It saves energy and power. It can save power by 1/3 than conventional down and feather filling machine. The fan’s soft start produces less impulse on the power source when it starts to run. Even a 5- ampere single phase electric meter can be adopted. It is quick to stop. It can stop down and feather being blown out within 1 second after the fan brake is applied. Thus it is easy to keep both the product and site tidy. It can be used in shop as a piece of equipment for on-spot filling of down and feather quilts. It can also be combined in a large scale production line in factory.

(2) Selection of down and feather holding box

Down and feather holding box with the size of 620 x 520 x 750 (mm) can be selected for shops. It weighs about

Big down and feather holding box with the size of 650 x 550 x 750 (mm) can be adopted for factories. It weighs about

(3) Selection of down and feather filling pipe

Down and feather filling pipe with hard joint is preferred in big workshops because it’s convenient, fast, solid and endurable. It is not easy to get blocked because of its smooth inside wall.

Down and feather filling pipe with soft joints can be adopted even in shops or in other narrow places because it is flexible to turn around. But the resistant force during the filling process is big. The joint has a working life of about two years.

Down and feather filling pipe with a diameter of

Down and feather filling pipe with a diameter of

Down and feather filling pipe with a diameter of 32-

Fan outlet with a diameter of

The bigger the pipe is, the fast its filling speed and the less tendency to get blocked.

Down and feather filling pipe with sieve holes should be adopted to fill down and feather into products made of air tight textiles.

(4) Down and feather filling machine for quilts can also be used to fill small batch of pillows. For machines specially used to fill pillow and cushion, please select filling machine for pillow ( chemical fiber filling machine ). Its filling speed of the motor doubles that of filling machine for quilt.

Clothes feather filling machine doesn’t have the synthetic glass filter vat. So the filling mouth is lower, only

QF-2 Strapped Clothes Feather Filling Machine

Use the compressed air to fill the feather clothes. It is applicable for the filling of strapped feather clothes.. One electric scale, two filling mouths, and three operating workers, enables the machine to fill one stripe in 4 seconds without blockage. It’s the fastest and most efficient machine with the best cost performance.

It’s best to fill less than